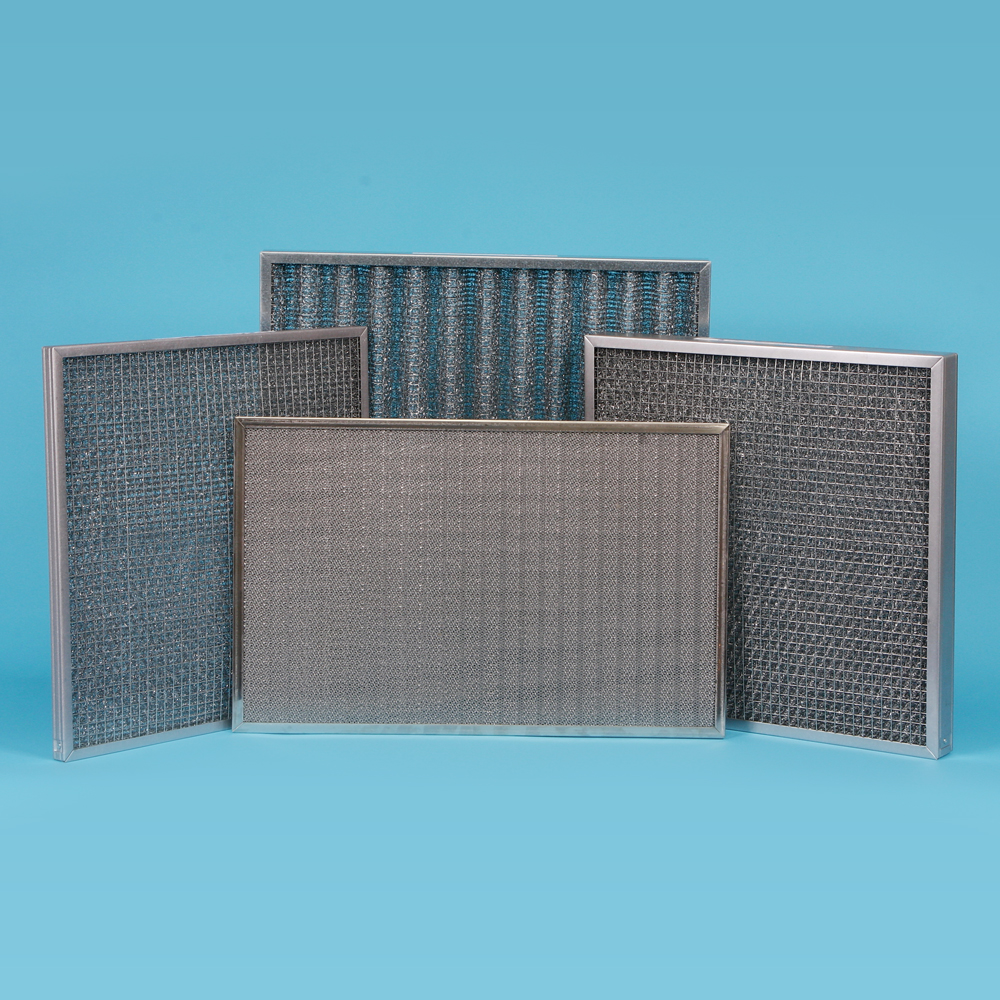

They are strong filtering cells at medium efficiency and they are composed of a labyrinth structure filtering mattress having several knitted aluminium flat wire layers, kept by two zinc-plated wire nets and boxed into a galvanized steel frame.

APPLICATIONS

They are used for fan-coil, air treatment units, warm air generators, ventilation equipment of machines, as pre-filters to filters with higher performances, as filters for hoods and drops separators.

FEATURES

According to EN 779:2012 Standards, the filtration classes of these filters is G2/G3. It is possible to get different filtering characteristics by changing the number of metallic layers composing the media and/or moistening the filters by adhesive oils.

The table below shows the capacities and the pertaining initial resistance for the standard sizes.

| dimensions [mm] | capacity [m3/h] | pressure drop [Pa] | capacity [m3/h] | pressure drop [Pa] | ||

| sp. 23 mm | sp. 48 mm | sp. 23 mm | sp. 48 mm | |||

| 400 x 500 | 630 | 15 | 25 | 950 | 25 | 40 |

| 400 x 625 | 800 | 1200 | ||||

| 500 x 500 | 800 | 1200 | ||||

| 500 x 625 | 1010 | 1520 | ||||

| 595 x 595 | 1140 | 1710 | ||||

| 287 x 595 | 520 | 780 | ||||

The limit working temperature is higher than 100°C. The CM filtering cells can be supplied with different dimensions and thicknesses from the standard above ones, with zinc-plated mattresses (CM/ZN type), entirely in aluminium (CMA type) or in AISI 304 stainless steel (CXC type).

INSTALLATION & SERVICE

The CM filters can be installed into C-shaped guides or into holding frames at frontal access. Replace or regenerate the cells once having reached a resistance of 200 Pa. Clean by shaking (in case of rough and dry dust) or by counter current air or by warm water and cleaning agent, then, if necessary, grease again the filter with adhesive oil.